Minimum Selling Price (MSP) Estimator

This tool uses an algorithm called pyTEA to

estimate MSP of biofuels and bioproduct. Details of

pyTEA

and its prediction error are provided here.

pyTEA is a process-based simulation model designed to

approximate costs

of major supply and production stages for a given

molecule.

While lacking the nuance and precision of

industry-grade software such as SuperPro Designer

or Aspen Plus, it aims to roughly emulate the methods of

these programs and generate comparable outputs

in a fast and lightweight manner.

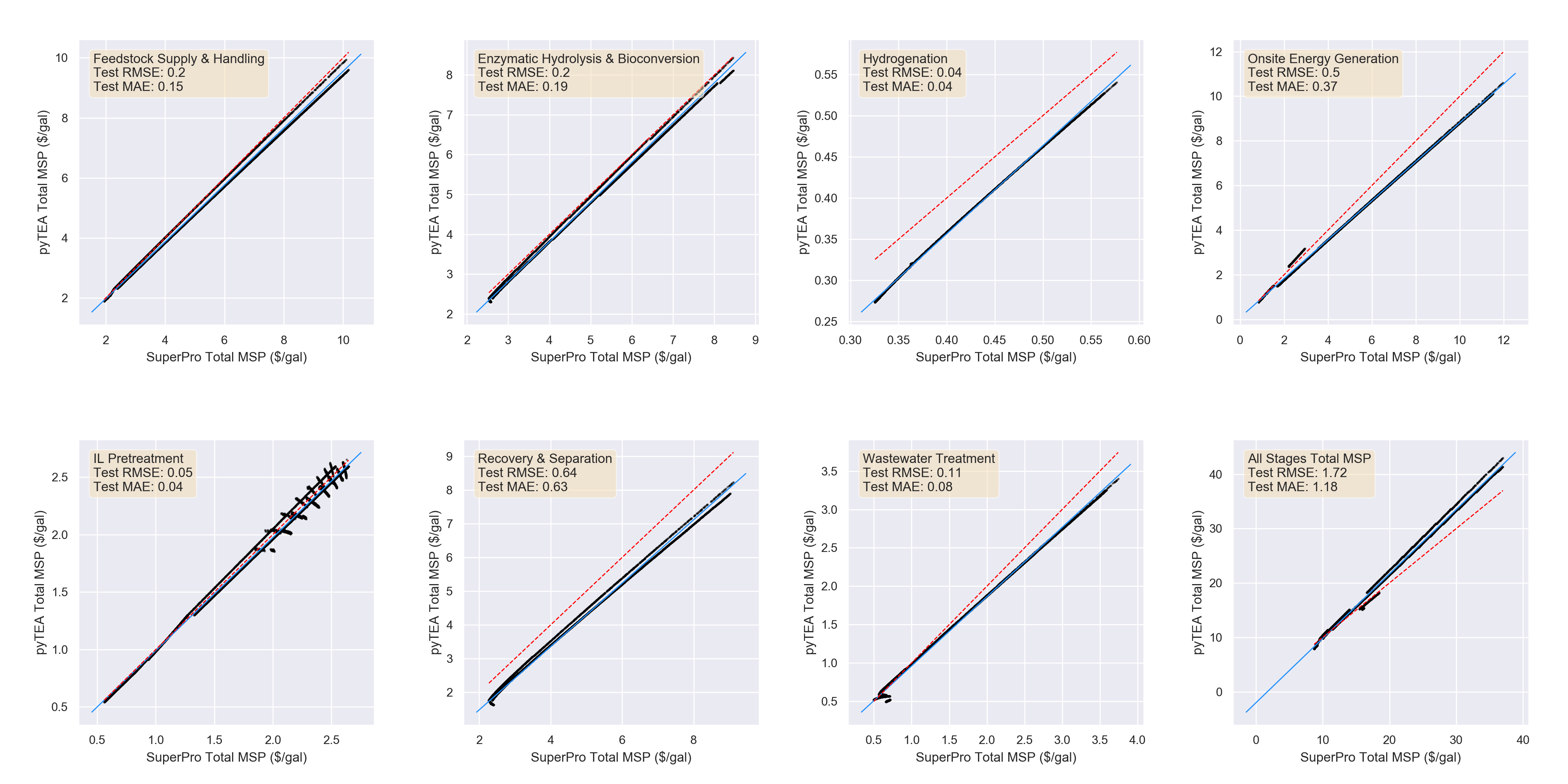

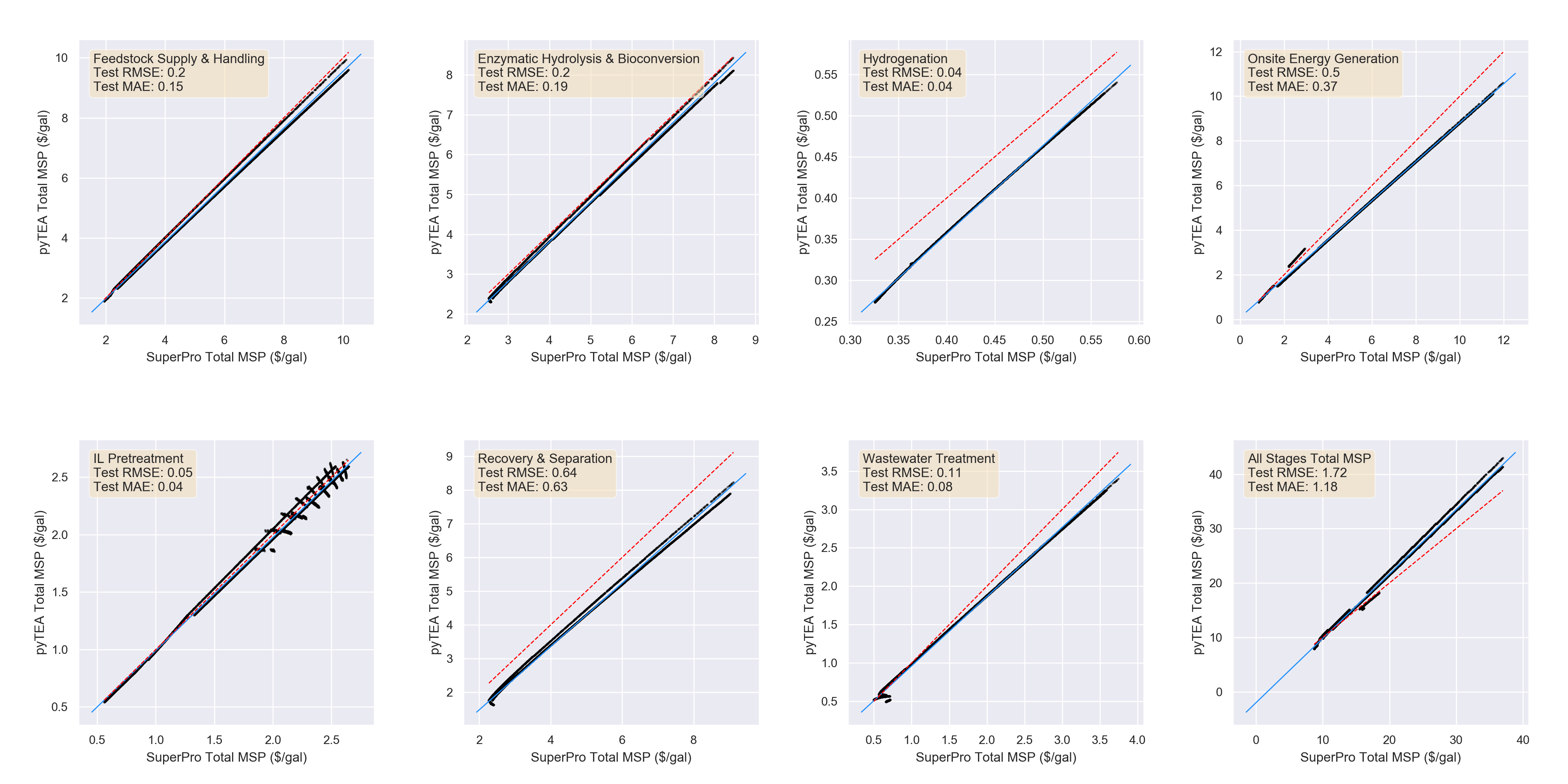

To validate the accuracy of pyTEA

we first ran 2,000

simulation trials of a SuperPro model for bioethanol

production from lignocellulosic biomass.

For each trial, values of the

input parameters were drawn randomly from their

respective

probability distributions. We treat the MSP values

generated

SuperPro in these trials as the 'ground truth' as they

are

derived from the most precise mechanistic method

available.

We then used pyTEA to make predictions on each of the

2,000 simulation trials. The scatterplots below show the

correlations between the SuperPro MSP values for each

trial

and the corresponding pyTEA prediction

for the same set of input parameter values.

pyTEA

A greater clustering of points around the y = x line

(dashed red) in these plots indicates closer agreement

between

predicted and actual values, and thus higher prediction

accuracy.

Quantitatively, we rely on

Mean Absolute Error

(MAE) as our primary metric of model prediction error.

Conceptually, MAE simply measures the average difference

between

predicted and ground truth values and therefore offers

easily

interpretable error margins in the same units as the

target

variable. In terms of total MSP, pyTEA achieves an MAE

of

1.18 $/gal.

Final Product:

Final Product: